Dyeing

Dyeing is a process that allows, at a microscopic scale, to integrate color to a material.

There are several ways to add color :

- Mass dyeing : Synthetic and artificial process only, color loads are mixed with the polymer chips during the extrusion process. This results in a high level of dye fastness.

- Flock dyeing

- Roving dyeing

- Yarns dyeing : Process for textiles with non-printed patterns (e.g.: stripes, houndstooth, etc.)

- Fabric dyeing : The most common and easiest technique to implement, valid only for plain textiles.

- Dyeing on finished articles

Methodologies

Types of dyes

Dyes for aqueous bath

Used for natural and artificial materials, there are many dyes, the choice depends on the textile composition. If the textile is composed of two or more different origins fibers, it is necessary to ensure that none of the materials is degraded.

Most of the time, we used direct or reactive dye on cellulosic fibers, and acid dye for animal fibers.

Dispersed dye

Used for synthetic materials that cannot be dyed in aqueous baths, because they are hydrophobic.

We used a lot of chemical agents and dying assistants to improve the affinity between the fiber and the dye.

The main dyeing process

Dyeing process

- Jigger: The fabric, on a roll, is drawn into a bath, then onto another roll. This operation is performed several times.

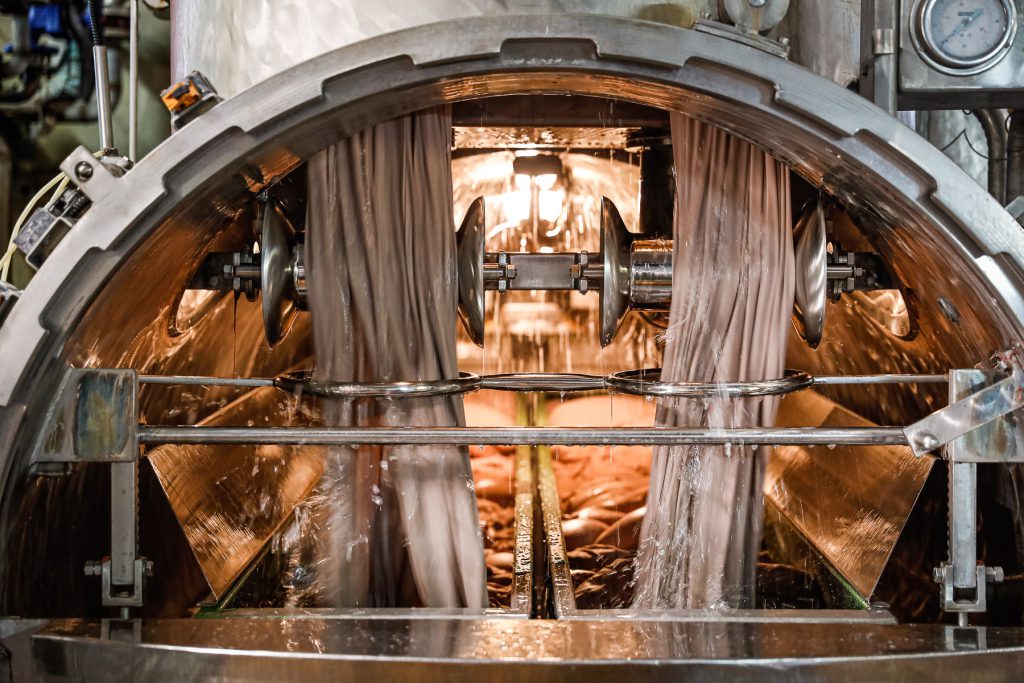

- Autoclave: The dye bath is circulated, under pressure, at a temperature above 100°C. Among the various techniques of dyeing in autoclave, there is the beam of fabric.

The fabric or yarn is placed on perforated cylinders, the dye is dissipated under pressure through the perforations of the cylinder to dye the material. - Padding : The fabric is dyed using a padd. This means that the fabric passes (continuously) through a dye bath, then is extruded (pressed) between two rollers to make the dye penetrate the heart of the fiber.

- Free dyeing : The fabric is rotated in a machine containing a static dye bath.